產(chǎn)品展示

Product display

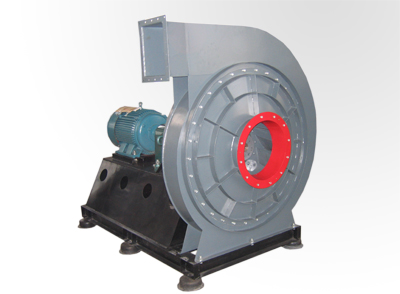

8-09,9-12 pressure centrifugal fan

Patent No.:

★ Overview

8-09,9-12 pressure centrifugal fan with the melting rate of 1,2,3,5,7 t / h cupola supporting the dedicated fan can also be used as a variety of furnaces , blast Forge purposes in other industries conveying air and not spontaneous , non-sticky material gases are also widely used.

The company introduced a new 8-09,9-12 pressure centrifugal fan , its aerodynamic performance is consistent with the original machine , assembly type and body structure has greatly improved in appearance , strength, range of applications , and other aspects to improve .

★ Type and Structure

A machine number

1.1 8-09 have 6.8,7.1,8,8.5,9 five machine number ;

1.2 9-12 have 6.8,7.1,7.4,7.7,8,9 six machine number . ( Machine numbers multiplied by 100 equals the effective diameter of the impeller , in mm)

2 Transmission

All gauges are two kinds of A -type and transmission mode

A formula - Direct drive motor

D -type - motor via a coupling, transmission bearing housing

3 assembly type

3.1 fan can be made L (N) and D (S) two kinds of rotation type, direction from the motor , impeller counterclockwise (N) spin left-handed ; impeller clockwise (S) is right-handed .

3.2 the fan outlet in a horizontal position as a reference point , can be made 0 °, 45 °, 90 ° 135 °, 180 °, 225 °, 270 ° seven kinds of patterns.

3.3 Whether A type or D type , fans are installed in all parts of the whole rack above the bottom of the rack is equipped with shock absorber soft contact with the ground , without a dedicated fan base .

Four major structural components

4.1 Impeller - by fans new and efficient theoretical design forward by the blades, front disc , rear disc and shaft plate welding composition, wherein the shaft plate adopts the international advanced drogue coupling mechanism , so that the impeller assembly and disassembly is extremely simple and fast. Impeller material can be selected according to the requirements of different high-quality carbon steel or corrosion-resistant stainless steel . After molding machines with advanced balance static and dynamic balance calibration, so smooth and reliable operation .

4.2 chassis ( including the front cover ) - a prototype based on the addition of a ring -shaped and radial ribs group so that positive and negative pressure bearing stiffness and greatly improve the performance of their material also can be selected according to the requirements of different high-quality carbon steel or corrosion-resistant stainless steel .

4.3 transmission mechanism ( only D -type ) - from the spindle , bearings, bearing housings , couplings and other components. Normal medium can be ordinary bearing housings , high temperature water cooling medium should be used bearing housing .

★ installation , commissioning and maintenance

1 check - should be checked before installation whether there are internal debris blower , if so, to be clear ; steers the impeller, if there is virtually scratch phenomenon , found inadequacies must be timely adjustments intact.

2 Foundation - thickness not less than 300mm concrete floor surface basic level, plus put on the rack around and not less than 300mm above the surrounding floor about 100mm ( waterproof ) .

3 duct connection - Fan flexible import and export shall be provided over and setting up a regulator valve ( at least one must be set ) , and then be connected with the duct system .

4 Commissioning - damper shall be closed before running the blower at no load condition starts to reach normal operating speed can be gradually open the valve until the rated condition. During operation should be strictly monitored current must not exceed rating. D fan running after 20 minutes should check the bearing housing temperature is normal ( temperature rise shall not exceed the ambient temperature 40 ℃, surface temperature should not exceed 70 ℃).

5 Maintenance - fan maintenance must first shut down power ; according to the actual situation in due course replace the lubricant ( oil or grease ) ; increased vibration occurs when the fan , bearing temperature is too high , the motor current is too large body of overheating are not normal circumstances , should promptly identify the reasons for troubleshooting before running again.

★ 8-09 high pressure centrifugal fan performance tables

Machine number Speed rpm No. Flow m3 / h Total pressure Pa Required power Kw Equipped with a motor 6.8 2900 1 675 10523 4.62 Y132S2-2 7.5kW 2 944 11026 5.82 3 1215 11374 7.15 4 1485 11439 8.63 Y160M1-2 11kW 5 1754 11341 10.28 6 2024 11063 11.96 Y160M2-2 15kW 7 2295 10634 13.60 7.1 2900 1 768 11472 5.53 Y132S1-2 5.5kW 2 1075 12021 6.96 Y132S2-2 7.5kW 3 1383 12371 8.71 Y160M1-2 11kW 4 1690 12471 10.42 5 1997 12364 12.30 Y160M2-2 15kW 6 2304 12061 14.35 7 2612 11594 16.61 Y160L-2 18.5kW 8 2919 11061 18.38 8 2950 1 1110 14876 10.36 Y160M1-2 11kW 2 1554 15579 13.04 Y160M2-2 15kW 3 1998 16033 16.31 Y160L-2 18.5kW 4 2442 16163 19.51 Y180M-2 22kW 5 2887 16023 23.04 Y200L1-2 30kW 6 3331 15632 26.88 7 3775 15026 31.11 Y200L2-2 37kW 8 4219 14277 34.43 8.5 2950 1 1341 17013 14.32 Y160M2-2 15kW 2 1877 17828 18.02 Y160L-2 18.5kW 3 2414 18347 22.54 Y200L1-2 30kW 4 2950 18496 26.97 5 3487 18338 31.85 Y200L2-2 37kW 6 4023 17888 37.15 Y225M-2 45kW 7 4560 17196 43.00 9 2950 1 1591 19073 19.05 Y180M-2 22kW 2 2228 19988 23.98 Y200L1-2 30kW 3 2865 20569 30.00 4 3502 20736 35.90 Y200L2-2 37kW 5 4138 20588 42.37 Y225M-2 45kW 6 4775 20054 49.44 Y250M-2 55kW 7 5412 19278 57.23 Y280S-2 75kW 8 6049 18318 63.33

★ 9-12 high pressure centrifugal fan performance tables

Machine number Speed rpm No. Flow m3 / h Total pressure Pa Required power Kw Equipped with a motor 6.8 2900 1 1700 11590 9.32 Y160M2-2 15kW 2 2160 11820 11.59 3 2620 12000 13.57 4 3080 12140 15.93 Y160L-2 18.5kW 5 3540 12120 18.27 6 4000 11980 20.55 Y180M-2 22kW 7 4460 11740 22.60 7.1 2900 1 2074 12347 12.10 Y160M2-2 15kW 2 2658 12661 15.02 3 3000 12807 16.43 Y160L-2 18.5kW 4 3242 12896 18.02 5 3826 13024 21.14 Y180M-2 22kW 6 4410 12935 24.30 Y200L1-2 30kW 7 4990 12739 27.65 7.4 2950 1 2349 13416 14.88 Y160M2-2 15kW 2 3010 13749 18.47 Y160L-2 18.5kW 3 3371 14004 22.16 Y180M-2 22kW 4 4332 14142 25.99 Y200L1-2 30kW 5 4993 14053 29.89 6 5654 13838 33.99 Y200L2-2 37kW 7 6315 13465 38.07 Y225M-2 45kW 7.7 2950 1 2349 14543 15.81 Y180M-2 22kW 2 3010 14887 19.60 3 3371 15171 23.52 Y200L1-2 30kW 4 4332 15319 27.59 5 4993 15220 31.72 Y200L2-2 37kW 6 5654 14985 36.07 7 6315 14583 40.40 Y225M-2 45kW 8 2950 1 2996 16216 22.97 Y200L1-2 30kW 2 3824 16528 28.24 3 4651 16931 33.98 Y200L2-2 37kW 4 5478 17096 39.78 Y225M-2 45kW 5 6306 16931 45.52 6 7133 16729 51.83 Y250M-2 55kW 9 2970 1 4295 20803 42.24 Y225M-2 45kW 2 5481 21202 51.93 Y250M-2 55kW 3 6667 21719 62.48 Y280S-2 75kW 4 7853 21931 73.15 5 9039 21719 83.71 Y280M-2 90kW