«a(chĘún)ĂĚŇ╣╩ż

Product display

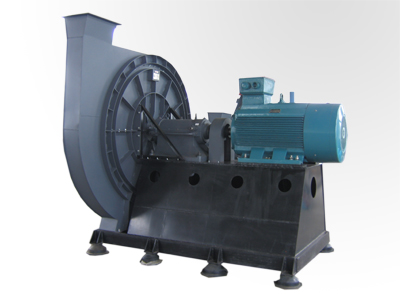

9-19,9-26 pressure centrifugal fan

Patent No.:

í´ Overview

9-19,9-26 pressure centrifugal fan , generally used for blacksmith furnace and high pressure forced ventilation , and can be widely used for transportation of materials, conveying air and not spontaneous , non-sticky material gases. The technical performance parameters according to the medium is designed to determine the standard state of the air , it can also serve as the practical application of high-temperature corrosive gases and gas transport , this time the physical properties of the transmission medium should be converted into the standard state properties of the air again Selection . When the parameters, structure have special requirements , the Company may be non-standard design alone .

The company introduced a new 8-09,9-12 pressure centrifugal fan , its aerodynamic performance is consistent with the original machine , assembly type and body structure has greatly improved in appearance , strength, range of applications , and other aspects to improve .

í´ Type and Structure

A machine number

The fans have a total of thirteen íÝ 4,4.5,5,5.6,6.3,7.1,8,9,10,11.2,12.5,14,16 machine number .

( Machine numbers multiplied by 100 equals the effective diameter of the impeller , in mm)

2 Transmission

íÝ 4 ~ 6.3 for the A -type transmission ; íÝ 7.1 ~ 16 for the D -type transmission .

A formula - Direct drive motor

D -type - motor via a coupling, transmission bearing housing

3 assembly type

3.1 fan can be made L (N) and D (S) two kinds of rotation type, direction from the motor , impeller counterclockwise (N) spin left-handed ; impeller clockwise (S) is right-handed .

3.2 the fan outlet in a horizontal position as a reference point , can be made 0 íŃ, 45 íŃ, 90 íŃ 135 íŃ, 180 íŃ, 225 íŃ, 270 íŃ seven kinds of patterns.

3.3 Whether A type or D type , fans are installed in all parts of the whole rack above the bottom of the rack is equipped with shock absorber soft contact with the ground , without a dedicated fan base .

Four major structural components

4.1 Impeller - by fans new and efficient theoretical design forward by the blades, front disc , rear disc and shaft plate welding components. Impeller material can be selected according to the requirements of different high-quality carbon steel or corrosion-resistant stainless steel . After molding machines with advanced balance static and dynamic balance calibration, so smooth and reliable operation .

4.2 chassis ( including the front cover ) - a prototype based on the addition of a ring -shaped and radial ribs group so that positive and negative pressure bearing stiffness and greatly improve the performance of their material also can be selected according to the requirements of different high-quality carbon steel or corrosion-resistant stainless steel .

4.3 transmission mechanism ( only D -type ) - from the spindle , bearings, bearing housings , couplings and other components. Normal medium can be ordinary bearing housings , high temperature water cooling medium should be used bearing housing .

í´ installation , commissioning and maintenance

1 check - should be checked before installation whether there are internal debris blower , if so, to be clear ; steers the impeller, if there is virtually scratch phenomenon , found inadequacies must be timely adjustments intact.

2 Foundation - thickness not less than 300mm concrete floor surface basic level, plus put on the rack around and not less than 300mm above the surrounding floor about 100mm ( waterproof ) .

3 duct connection - Fan flexible import and export shall be provided over and setting up a regulator valve ( at least one must be set ) , and then be connected with the duct system .

4 Commissioning - damper shall be closed before running the blower at no load condition starts to reach normal operating speed can be gradually open the valve until the rated condition. During operation should be strictly monitored current must not exceed rating. D fan running after 20 minutes should check the bearing housing temperature is normal ( temperature rise shall not exceed the ambient temperature 40 íŠ, surface temperature should not exceed 70 íŠ).

5 Maintenance - fan maintenance must first shut down power ; according to the actual situation in due course replace the lubricant ( oil or grease ) ; increased vibration occurs when the fan , bearing temperature is too high , the motor current is too large body of overheating are not normal circumstances , should promptly identify the reasons for troubleshooting before running again.

í´ 9-26 high pressure centrifugal fan performance table

Machine number Speed rpm Flow m3/h Total pressure Pa Internal Efficiency% Internal powerkW Required powerkW Equipped with a motor 4A 2900 2198 3852 74.7 3.11 3.7 Y132S1-2 5.5kW 2368 3820 75.5 3.28 3.9 2536 3765 75.7 3.46 4.1 2706 3684 75.0 3.65 4.4 2877 3607 73.8 3.86 4.6 3044 3502 72.1 4.06 4.9 3215 3407 70.0 4.29 5.2 4.5A 2900 3130 4910 76.1 5.51 6.3 Y132S2-2 7.5kW 3407 4863 77.1 5.87 6.8 3685 4776 77.1 6.24 7.2 3963 4661 76.0 6.64 7.6 4237 4545 74.5 7.06 8.1 4515 4412 72.3 7.54 8.7 Y160M1-2 11kW 4792 4256 70.0 7.98 9.2 5A 2900 4293 6.35 77.2 9.12 10.5 Y160M2-2 15kW 4706 5984 78.2 9.80 11.3 5114 5896 78.0 10.48 12.0 5527 5725 76.7 11.23 12.9 5941 5553 74.9 12.00 13.8 6349 5381 72.7 12.81 14.7 6762 5180 70.0 13.65 15.7 Y160L-2 18.5kW 5.6A 2900 6032 7610 77.2 16.09 18.5 Y180M-2 22kW 6612 7546 78.2 17.27 19.8 7185 7400 78.0 18.47 21.2 7766 7218 76.7 19.79 22.8 8346 7000 74.9 21.15 24.3 Y200L1-2 37kW 8919 6781 72.7 22.57 26.0 9500 6527 70.0 24.06 27.7 6.3A 2900 8588 9698 77.2 28.99 33.3 Y225M-2 45kW 9415 9616 78.2 31.12 35.8 10230 9429 78.0 33.28 38.3 11056 9195 76.7 35.66 41.0 11883 8915 74.9 38.12 43.8 12699 8636 72.7 40.67 46.8 Y250M-2 55kW 13525 8310 70.0 43.35 49.9

|

Machine number |

Speed rpm |

Flow m3/h |

Total pressure Pa |

Internal Efficiency% |

Internal powerkW |

Required powerkW |

Equipped with a motor |

|

7.1D |

2900 |

12292 |

12427 |

77.2 |

52.70 |

61.8 |

Y280S-2 75kW |

|

13475 |

13231 |

78.2 |

56.57 |

66.4 | |||

|

14643 |

12078 |

78.0 |

60.49 |

71.0 | |||

|

15826 |

11776 |

76.7 |

64.84 |

76.1 |

Y315S-2 110kW | ||

|

17009 |

11415 |

74.9 |

69.30 |

81.3 | |||

|

18177 |

11055 |

72.7 |

73.94 |

86.8 | |||

|

19360 |

10635 |

70.0 |

78.82 |

92.5 | |||

|

8D |

2900 |

17584 |

15955 |

77.2 |

95.72 |

112.3 |

Y315M-2 132KW |

|

19277 |

15818 |

78.2 |

102.73 |

120.5 | |||

|

20947 |

15504 |

78.0 |

109.86 |

128.9 | |||

|

22640 |

15112 |

76.7 |

117.75 |

138.2 |

Y315L2-2 200KW | ||

|

24332 |

14644 |

74.9 |

125.85 |

147.7 | |||

|

26003 |

14177 |

72.7 |

134.28 |

157.6 | |||

|

27696 |

13634 |

70.0 |

143.14 |

168.0 | |||

|

1450 |

8792 |

3834 |

77.2 |

11.96 |

14.0 |

Y180M-4 18.5KW | |

|

9639 |

3802 |

78.2 |

12.84 |

15.1 | |||

|

10473 |

3729 |

78.0 |

13.73 |

16.1 | |||

|

11320 |

3638 |

76.7 |

14.72 |

17.3 | |||

|

12166 |

3529 |

74.9 |

15.73 |

18.5 | |||

|

13001 |

3421 |

72.7 |

16.79 |

19.7 |

Y200L-4 30KW | ||

|

13848 |

3294 |

70.0 |

17.89 |

21.0 | |||

|

9D |

1450 |

12518 |

4869 |

77.2 |

21.56 |

25.3 |

Y200L-4 30KW |

|

13723 |

4828 |

78.2 |

23.14 |

27.2 | |||

|

14913 |

4736 |

78.0 |

24.75 |

29.0 | |||

|

16118 |

4620 |

76.7 |

26.53 |

31.1 |

Y225M-4 45KW | ||

|

17322 |

4481 |

74.9 |

28.35 |

33.3 | |||

|

18512 |

4343 |

72.7 |

30.25 |

35.5 | |||

|

19717 |

4181 |

70.0 |

32.24 |

37.8 | |||

|

10D |

1450 |

17172 |

6143 |

80.4 |

35.69 |

41.9 |

Y250M-4 55KW |

|

19319 |

6056 |

81.2 |

39.19 |

46.0 | |||

|

21465 |

5920 |

80.4 |

43.02 |

50.5 | |||

|

23612 |

5761 |

78.6 |

47.10 |

55.3 |

Y280S-4 75KW | ||

|

25758 |

5560 |

76.0 |

51.35 |

60.3 | |||

|

27905 |

5309 |

73.0 |

55.35 |

65.0 | |||

|

30052 |

5065 |

70.0 |

59.34 |

69.6 | |||

|

11.2D |

1450 |

24126 |

7747 |

80.4 |

62.90 |

73.8 |

Y315S-4 110KW |

|

27142 |

7637 |

81.2 |

69.07 |

81.0 | |||

|

30157 |

7464 |

80.4 |

75.82 |

89.0 | |||

|

33173 |

7264 |

78.6 |

83.01 |

97.4 | |||

|

36189 |

7009 |

76.0 |

90.50 |

106.2 | |||

|

39205 |

6691 |

73.0 |

97.54 |

114.5 |

Y315M-4 132KW | ||

|

42221 |

6382 |

70.0 |

104.58 |

122.7 | |||

|

960 |

15973 |

3346 |

80.4 |

18.25 |

21.4 |

Y225M-6 30KW | |

|

17969 |

3299 |

81.2 |

20.04 |

23.5 | |||

|

19966 |

3225 |

80.4 |

22.00 |

25.8 | |||

|

21963 |

3140 |

78.6 |

24.09 |

28.3 | |||

|

23959 |

3031 |

76.0 |

26.26 |

30.8 |

Y250M-6 37KW | ||

|

25956 |

2895 |

73.0 |

28.31 |

33.2 | |||

|

27953 |

2763 |

70.0 |

30.35 |

35.6 |

|

Machine number |

Speed rpm |

Flow m3/h |

Total pressure Pa |

Internal Efficiency% |

Internal powerkW |

Required powerkW |

Equipped with a motor |

|

12.5D |

1450 |

33540 |

9713 |

80.4 |

108.91 |

127.8 |

Y315L1-4 160kW |

|

37732 |

9575 |

81.2 |

119.60 |

140.3 | |||

|

41925 |

9356 |

80.4 |

131.30 |

154.1 | |||

|

46117 |

9103 |

78.6 |

143.75 |

168.7 |

Y355M2-4 250kW | ||

|

50310 |

8782 |

76.0 |

156.70 |

183.9 | |||

|

54503 |

8381 |

73.0 |

168.90 |

198.2 | |||

|

58695 |

7993 |

70.0 |

181.10 |

212.5 | |||

|

960 |

22206 |

4179 |

80.4 |

31.61 |

37.1 |

Y280S-6 45kW | |

|

24981 |

4121 |

81.2 |

34.71 |

40.7 | |||

|

27757 |

4028 |

80.4 |

38.10 |

44.7 | |||

|

30533 |

3921 |

78.6 |

41.72 |

49.0 |

Y315S-6 75kW | ||

|

33309 |

3785 |

76.0 |

45.48 |

53.4 | |||

|

36084 |

3615 |

73.0 |

49.02 |

57.5 | |||

|

38860 |

3450 |

70.0 |

52.56 |

61.7 | |||

|

14D |

1450 |

47121 |

12285 |

80.4 |

191.94 |

225.2 |

Y355M2-4 250kW |

|

53011 |

12109 |

81.2 |

210.78 |

247.3 | |||

|

58902 |

11830 |

80.4 |

231.39 |

271.5 |

JS-138-4 410kW | ||

|

64792 |

11508 |

78.6 |

253.33 |

297.3 | |||

|

70682 |

11099 |

76.0 |

276.16 |

324.1 | |||

|

76572 |

10589 |

73.0 |

297.66 |

349.3 | |||

|

82463 |

10095 |

70.0 |

319.16 |

374.5 | |||

|

960 |

31197 |

5262 |

80.4 |

55.70 |

65.4 |

Y315S-6 75kW | |

|

35097 |

5188 |

81.2 |

61.17 |

71.8 | |||

|

38997 |

5071 |

80.4 |

67.15 |

78.8 |

Y315L1-6 110kW | ||

|

42897 |

4936 |

78.6 |

73.52 |

86.3 | |||

|

46796 |

4764 |

76.0 |

80.15 |

94.0 | |||

|

50696 |

4549 |

73.0 |

86.39 |

101.4 | |||

|

54596 |

4341 |

70.0 |

92.63 |

108.7 | |||

|

16D |

1450 |

70339 |

16250 |

80.4 |

374.22 |

439.1 |

JSQ-147-4 500kW (3000V) |

|

79131 |

16014 |

81.2 |

410.95 |

482.2 | |||

|

87923 |

15640 |

80.4 |

451.14 |

529.4 | |||

|

96716 |

15210 |

78.6 |

493.92 |

579.6 | |||

|

105500 |

14663 |

76.0 |

538.43 |

631.8 |

JSQ-158-4 850kW (3000V) | ||

|

114300 |

13983 |

73.0 |

580.35 |

681.0 | |||

|

123090 |

13324 |

70.0 |

622.26 |

730.2 | |||

|

960 |

46569 |

6911 |

80.4 |

108.60 |

127.4 |

Y355M1-6 185kW | |

|

52390 |

6813 |

81.2 |

119.26 |

139.9 | |||

|

58211 |

6659 |

80.4 |

130.92 |

153.6 | |||

|

64032 |

6481 |

78.6 |

143.34 |

168.2 | |||

|

69854 |

6254 |

76.0 |

156.25 |

183.3 | |||

|

75675 |

5971 |

73.0 |

168.42 |

197.6 |

Y355M3-6 220kW | ||

|

81496 |

5696 |

70.0 |

180.58 |

211.9 |